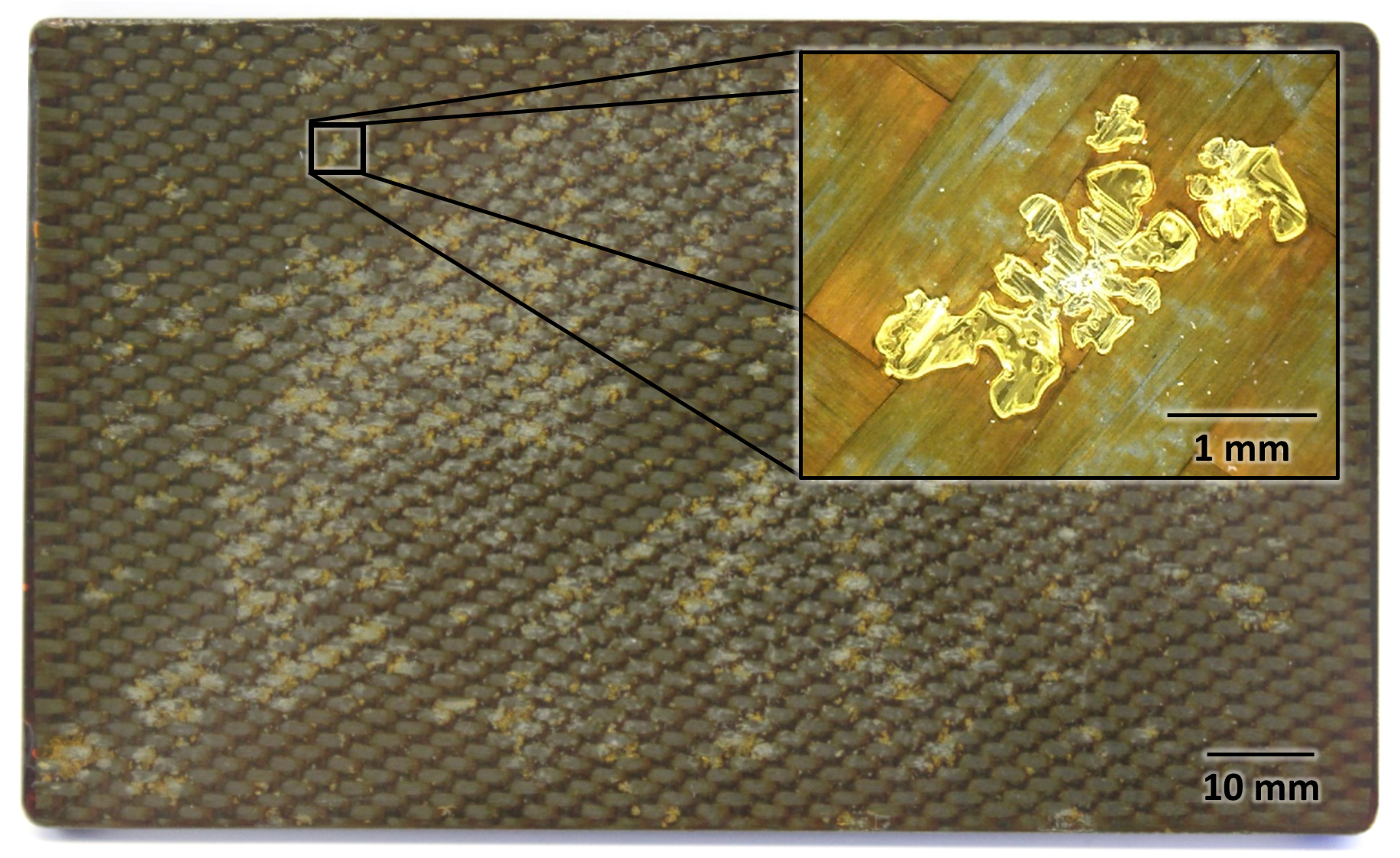

Surface porosity in a molded composite part.

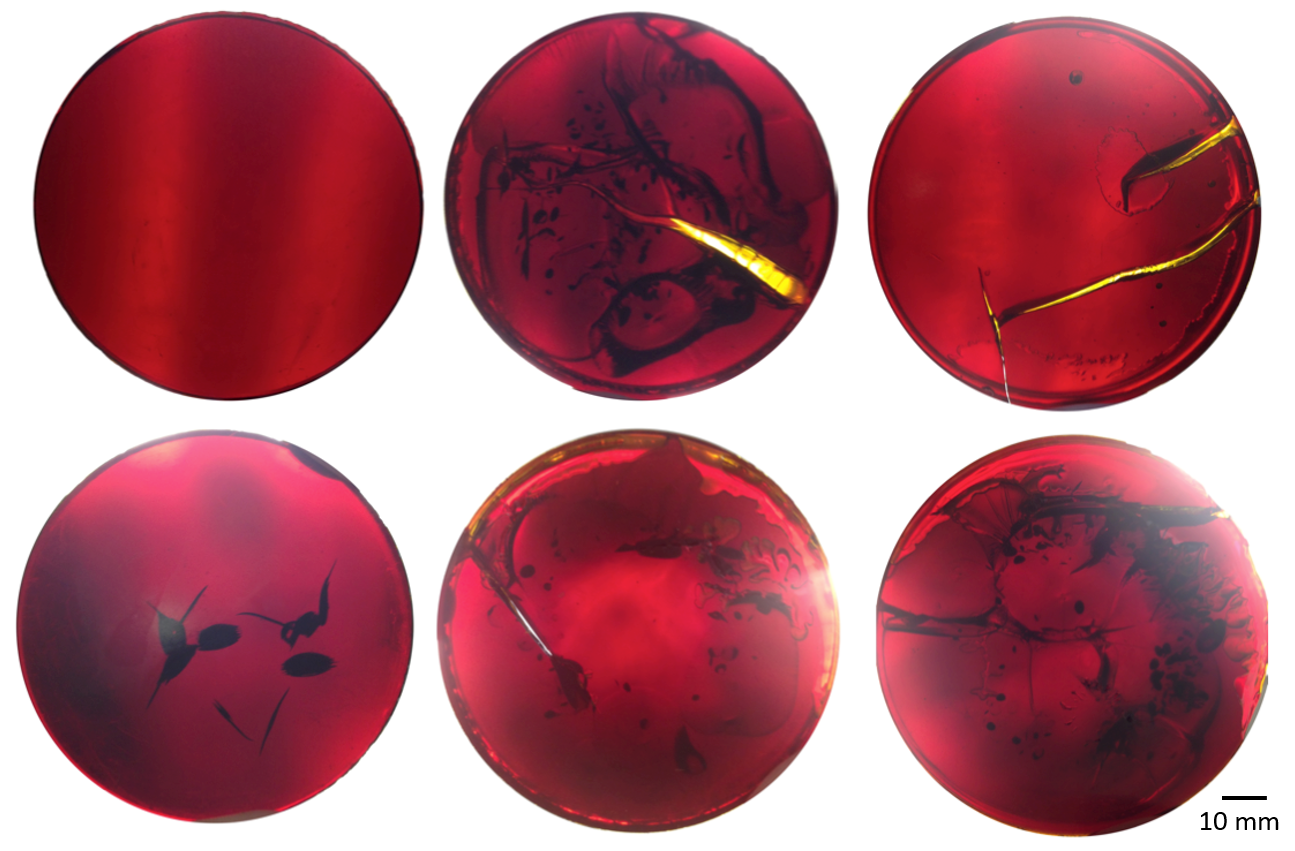

Volatile-induced voids in neat resin.

Project Title:

Eliminating Porosity in Resin Transfer Molding of Benzoxazine Composites

Researchers:

Mark Anders, Timotei Centea, Jonathan Lo

Summary:

This project investigates volatile-induced voids during the resin transfer molding (RTM) of composite parts based on a benzoxazine/epoxy blended thermoset resin and carbon fiber reinforcements. Lab-scale characterization techniques such as differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), a pressurizable reaction cell linked to a Fourier transform infrared spectroscopy (FTIR) are used to understand the resin’s polymerization, and relate the polymerization reaction kinetics to the nature and rate of volatile release.

This knowledge has been translated into science-based manufacturing guidelines to minimize the likelihood of defect formation, graphical maps designed to identify process windows and guide cure cycle selection, and a generic approach for optimizing cure using cure kinetics modeling. The results are validated in a highly instrumented RTM tool, which introduces the additional complications of non-uniform temperatures and pressures. Additionally, through both manufacturing and characterization experiments, the fundamental mechanisms of bulk and surface porosity formation for the RTM of benzoxazine resin systems have been elucidated.

Overall, the project has successfully connected investigation into fundamental chemical and physical phenomena with the development of a feasible, industrially-relevant process for RTM of benzoxazine systems. Future challenges include optimizing the manufacturing process for one (or a few) resin formulations for low defect levels and fast cycle times, through concurrent and coupled material re-formulation, process analysis, and process map development.

watch this