In situ Observation |

|

|---|---|

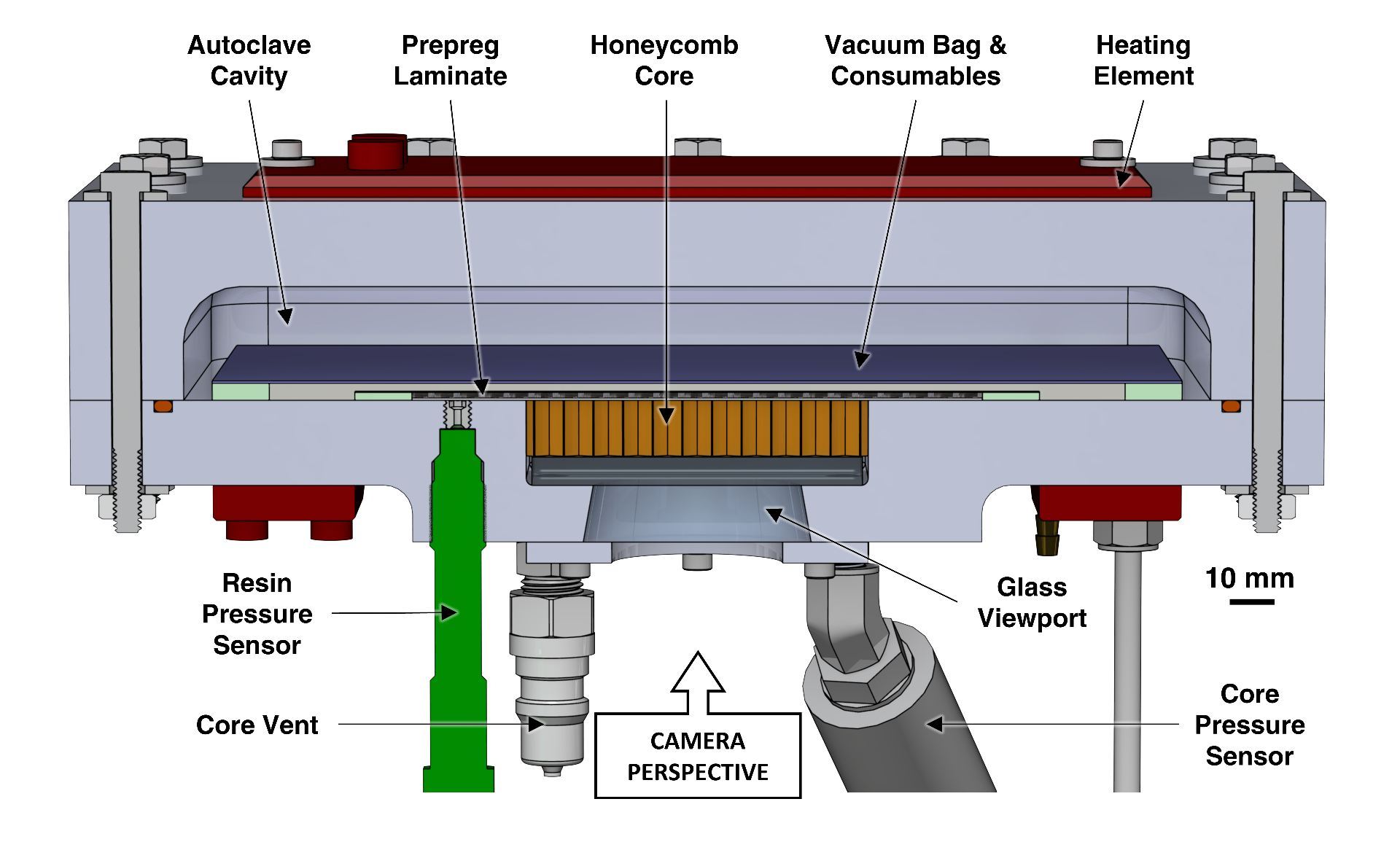

In situ Observable Autoclave

|

Curing Oven with In Situ Observation

Curing Oven with window which allows for in situ observation of cure processes. It facilitates the observation of void formation.

|

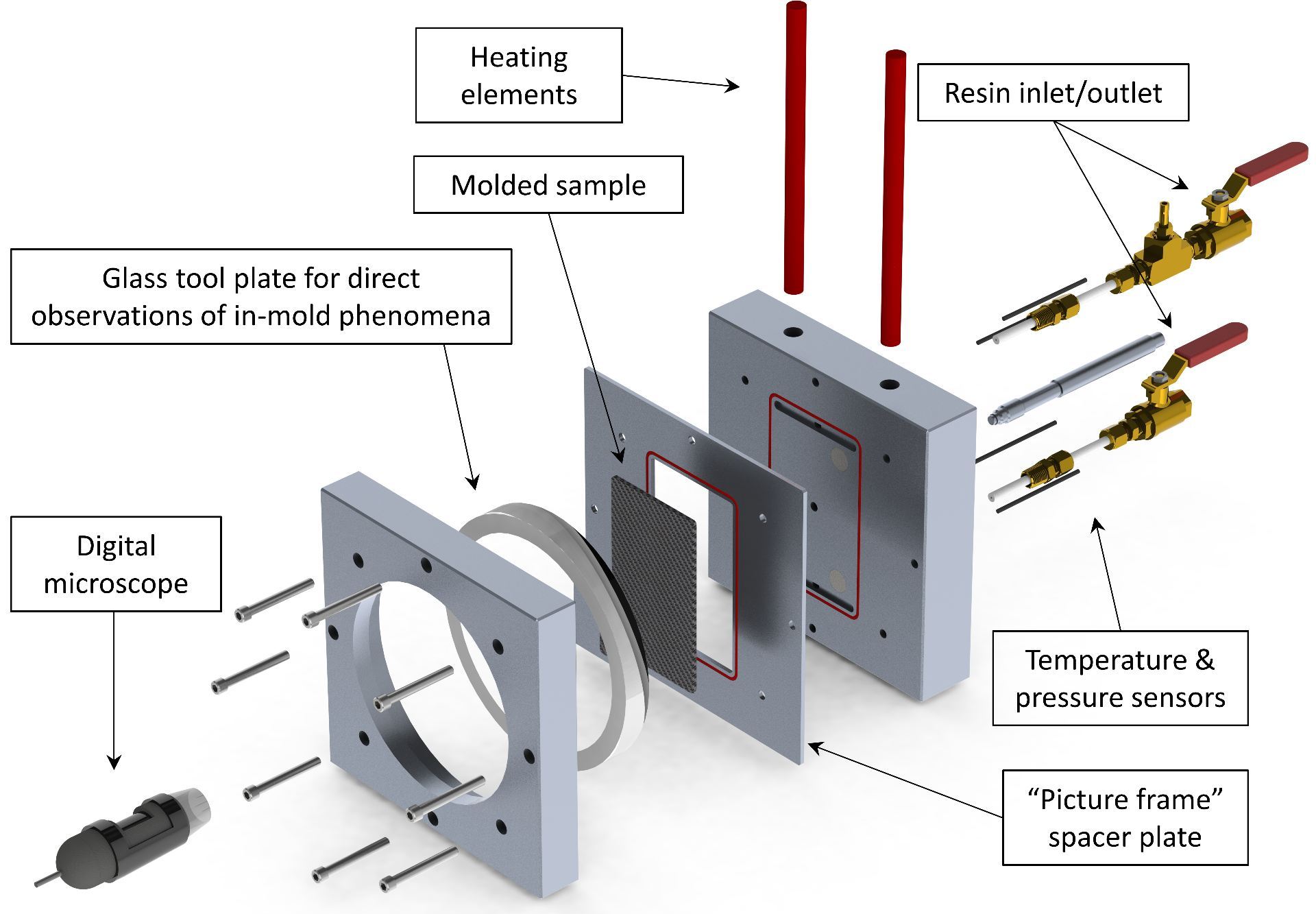

RTM Molding Tool with In Situ Observation

A custom-built lab-scale resin transfer molding (RTM) tool with embedded heaters, thermocouples, a pressure sensor, and in situ visualization capabilities.

|

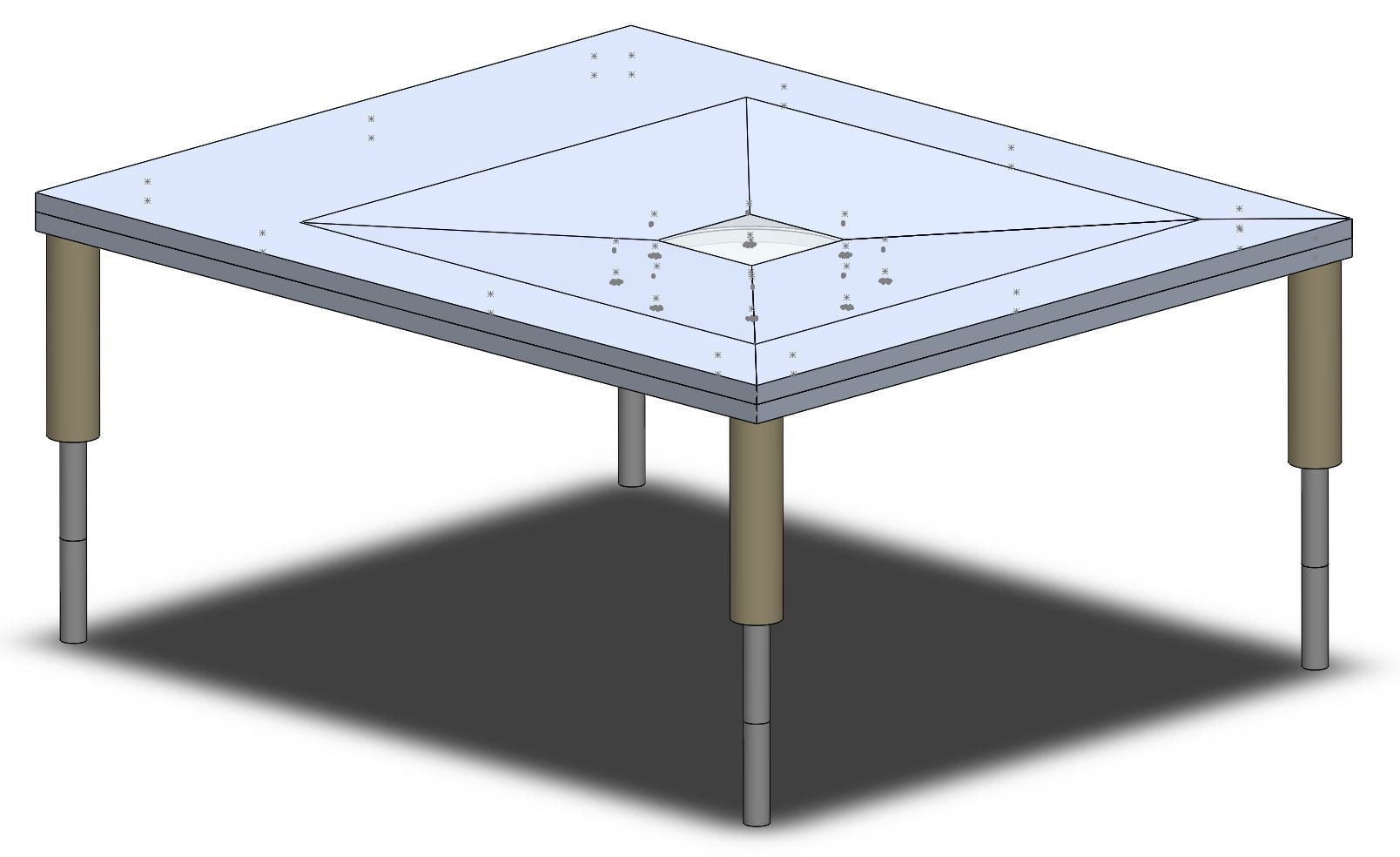

Scarf Repair Tool Plate with In Situ Observation

Custom-built lab-scale scarfed repair tool plate which allows in situ observation of repair processing conditions. |

Mechanical Testing |

|

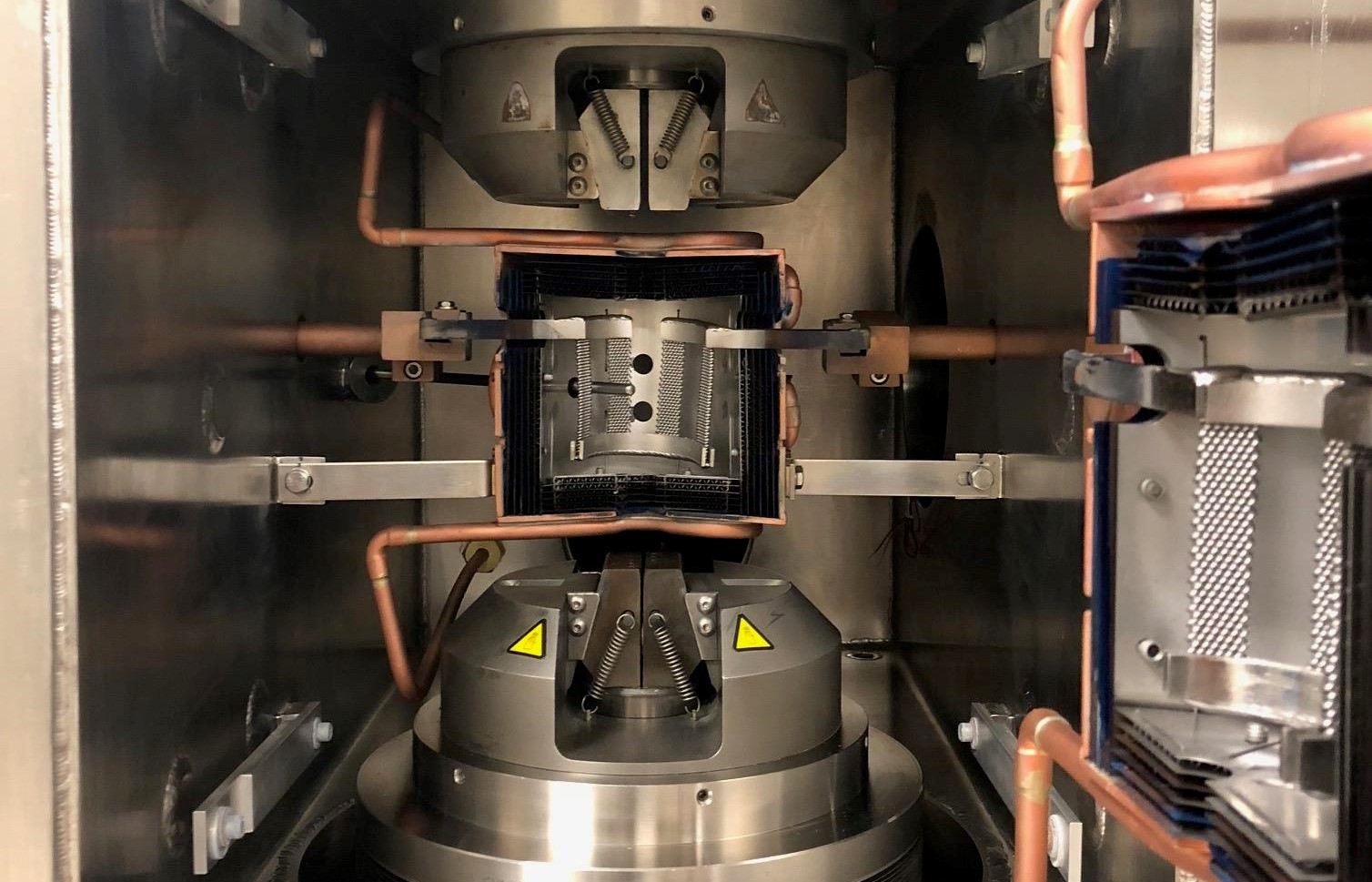

Vacuum Furnace Load Frame |

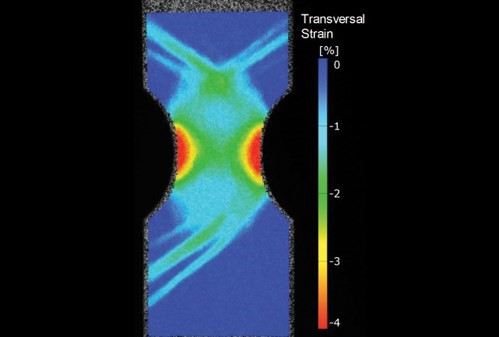

Non-Contact Optical 3D Deformation Measuring System

Non-Contact Optical 3D Deformation Measuring System for Mechanical Tests which allows for strain measurements in multiple directions without interfering with the part itself during the test.

|

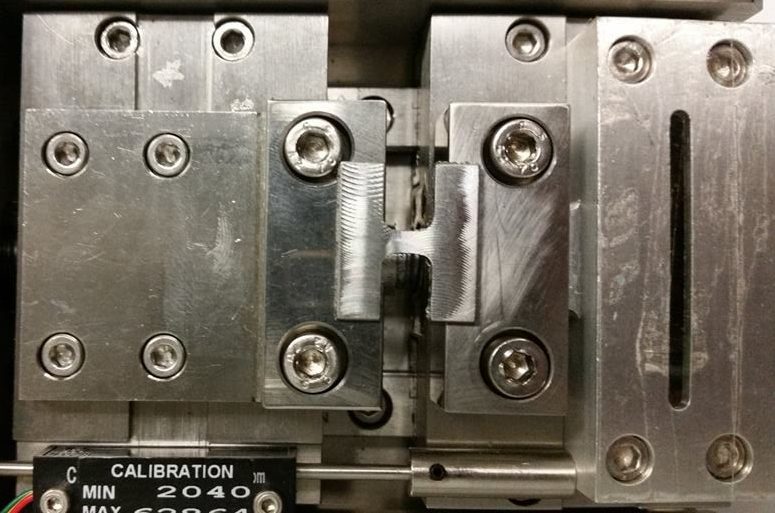

Microtensile Testing

Microtensile Testing for measuring mechanical properties of small samples. |

|

Other Capabilities |

|

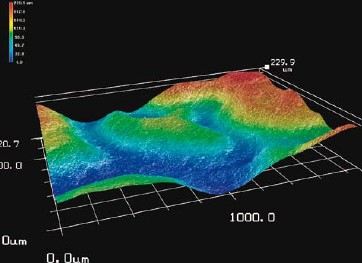

Digital Stereo Microscope with 3D Surface Profilometry |

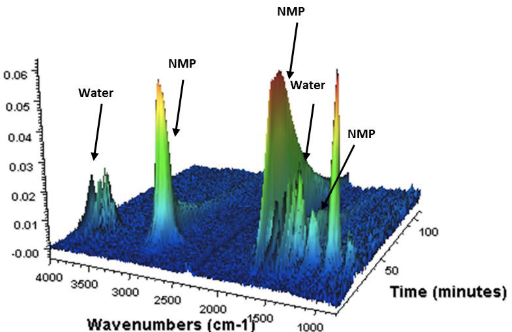

Reaction Cell with Fourier Transform Infrared Spectroscopy

Reaction Cell with Fourier Transform Infrared Spectroscopy which allows for volatile analysis on resins under temperature controlled conditions. Can be attached to our Thermogravimetric Analysis equipment to analyze the vapors released from samples. |

Heated Tool with Independent Temperature Zones

Heated tool with independently controlled temperature zones. This allows tests exploring the effect of heat gradients on part processing. |

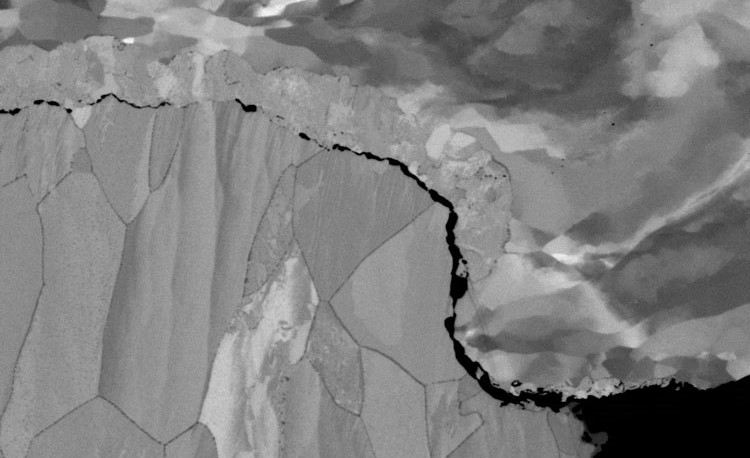

Ion Polisher

Ion Polisher which produces cross sections of hard and soft materials without any polishing damage. It allows for scanning electron microscopy sample preparation to analyze micro-scale defects. |

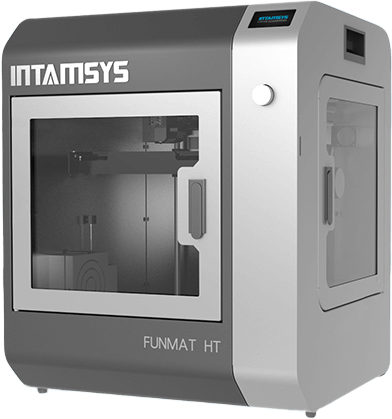

3D Printer

The FUNMAT HT is capable of 3D printing high-performance functional materials like PEEK, ULTEM and PPSU, in addition to a broad range of engineering thermoplastics. Users can achieve 50-micron high-resolution industrial quality.

|

|