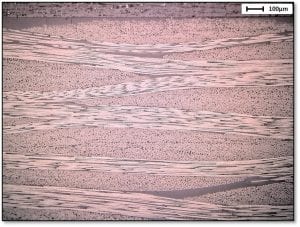

Cross-sectional micrographs of thermoformed 8-ply laminate

Researcher – Jay Jung Hwan Shin

Continuous fiber reinforced thermoplastics (CFRTPs) are less technically mature and less widely used than thermoset composites. However, interest in CFRTPs has grown rapidly across multiple industries including automotive, aerospace, and sporting goods, because of intrinsic advantages over thermoset counterparts: high material toughness, unlimited shelf-life, shorter production cycle time, recyclability, and weldability. Despite these advantages, extensive use of thermoplastic matrices has been restricted by the high melt viscosities and melting temperatures. To ensure proper impregnation of fiber beds and void removal, high-performance CFRTP parts must therefore be processed at high pressure and temperature. Consequently, costly investments in infrastructure and operations are required for CFRTP melt processing.

We demonstrate the feasibility of thermoplastic prepreg with a partially polymerized matrix, poly(methyl methacrylate) (PMMA) pre-polymer, and a carbon fiber reinforcement. The low viscosity polymeric precursor resin integrated into such CFRTP prepreg facilitated resin flow, allowing part consolidation at temperatures less than the final glass transition temperature of the matrix. Furthermore, the prepreg offered provisional tack and drape at room temperature for greater conformability. This work highlights the potential advantages of the proposed thermoplastic prepreg, which leverages the ability to utilize conventional thermoset prepreg processing capacities to manufacture thermoplastic composites, and identifies further processing challenges that must be addressed.