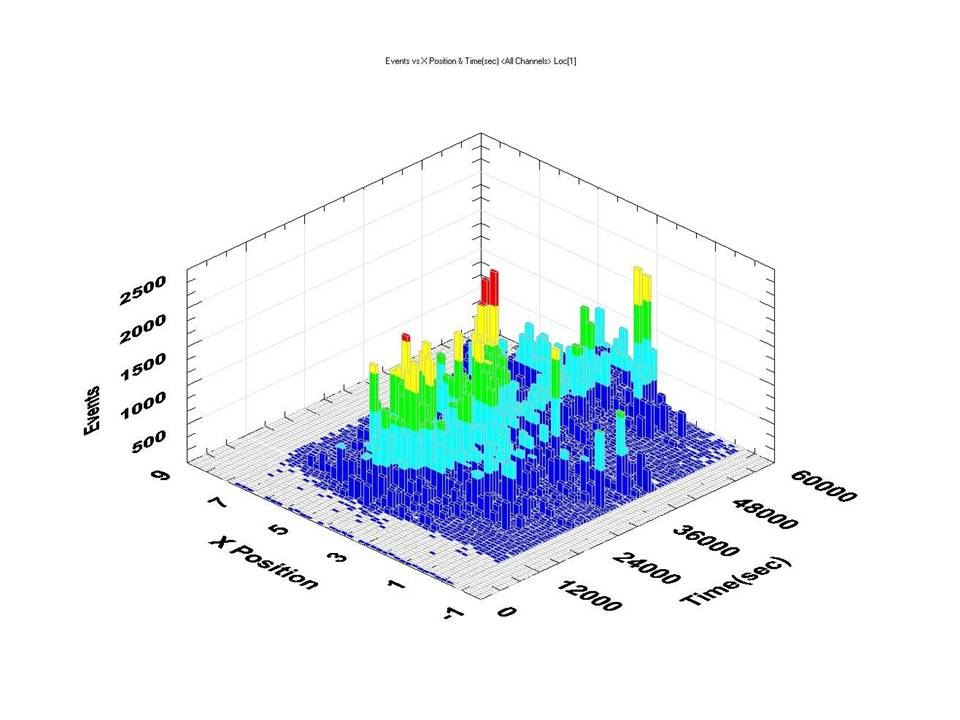

The plot below depicts the evolution of damage in a hybrid composite rod during a flexural fatigue test. The acoustic emission activity is concentrated at the center of the rod (x = 3.5) which experiences the highest relative bending moment, where events are maximum. The high event activity depicted in red, yellow and green is characteristic of short-burst, large energy release events such as fiber bundle breaks. The light and dark blue distributions are lower energy events that spread towards the sample ends and are characteristic of low amplitude, longitudinal and transverse matrix cracking.

The bending fatigue of the hybrid composite rod

(recorded by Keyence VW-6000 high speed camera)

watch here

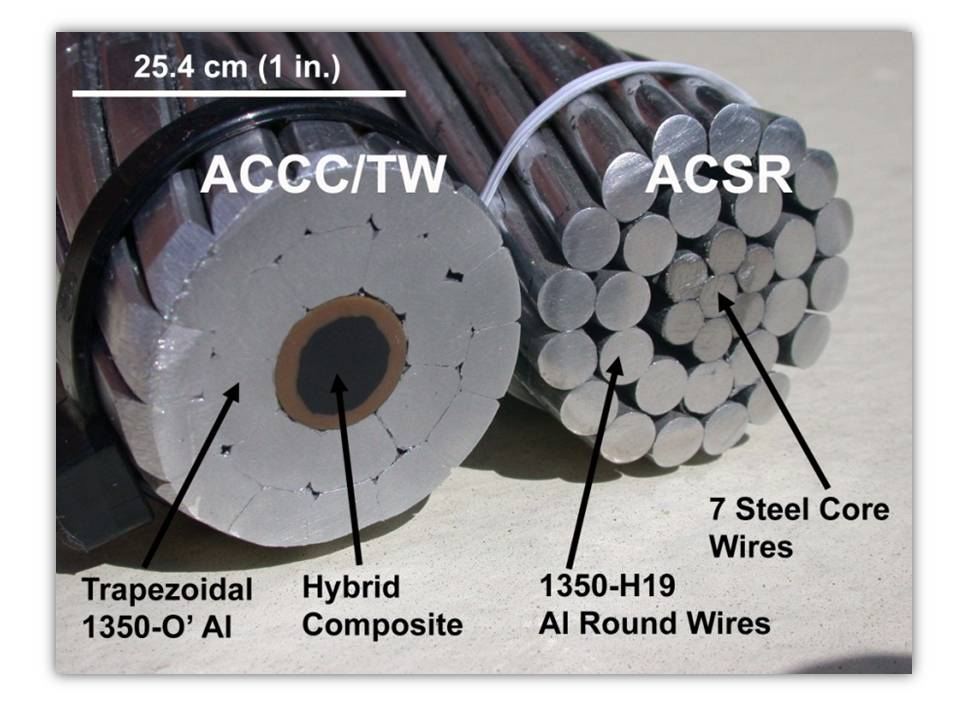

The next generation of overhead conductors for electrical will consist of aluminum wires wrapped around a solid composite rod, rather than a conventional steel cable. The advantage in replacing the stranded steel cable with a solid composite rod rests primarily in lower sag at high temperatures, which translates into increased ampacity, the capacity to transmit current. Increasing grid capacity is an important priority in the US, where grid capacity is barely adequate in a deregulated utility market. High efficiency conductors are also a top priority when installing new conductors, especially in developing countries such as China and India, and countries in South America, all of which face massive electrification needs. Multiple advantages accrue when steel-reinforced conductors are replaced with composite-reinforced conductors, but a major concern is long-term durability. These conductors are expected to last for decades with minimal maintenance, yet they hand from lattice towers with no insulation or protection from weathering. A major effort is underway at USC’s Composites Center to study the accelerated aging of composite rods used for conductor support. Aging experiments include exposure to temperature, moisture, cyclic loads (fatigue), and various aggressive environments, as well as the effects of combinations of these conditions. The focus is on mechanisms and kinetics of degradation, and the retention of mechanical properties and means for protecting against degradation. Computational models are developed and employed to predict longevity under representative aging conditions.

The next generation of power transmission lines will feature composite reinforcement to reduce sag at high temperatures, increase ampacity, and reduce line losses.