Researcher—Bill Edwards

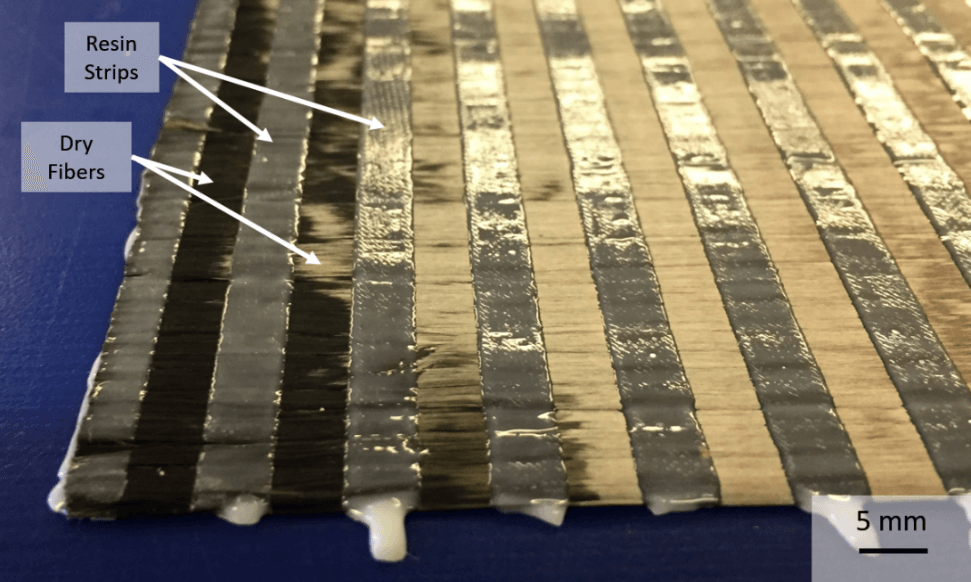

To improve the economics, flexibility, and speed of composite manufacturing, out-of-autoclave/vacuum bag-only (OoA/VBO) processing emerged as a low-cost alternative to traditional autoclave cure. While such techniques have been demonstrated to produce defect-free laminates under ideal conditions, OoA prepregs and VBO processing not sufficiently robust for widespread commercial adoption, particularly in the aerospace industry. This project explores the relationship between prepreg format, through-thickness permeability, and robust OoA manufacturing of prepreg laminates. A method for producing unidirectional USCpreg (UDSCpreg) using a mask-and-press technique has been developed for the creation of prepregs with customized resin distribution.

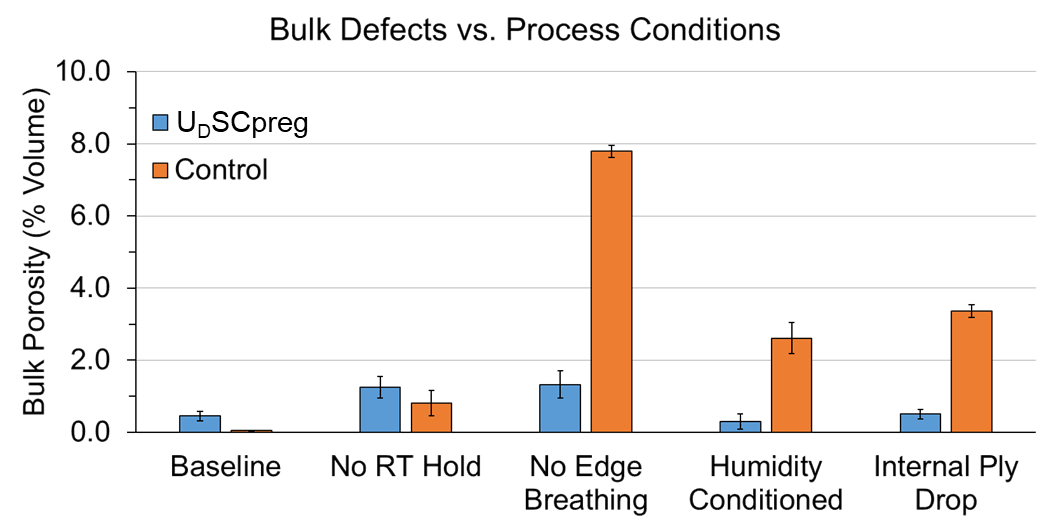

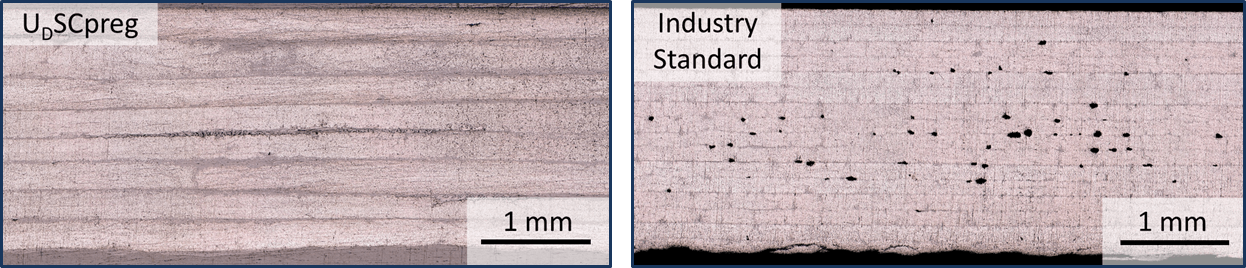

UDSCpreg provides convincing indications of the efficacy of introducing through-thickness evacuation pathways, despite being unoptimized and likely sub-optimal. Indeed, the surface porosity data collected on embossed UDSCpreg samples clearly demonstrates that subtle differences in resin topography can meaningfully influence laminate quality. Similar mechanisms operating to create surface porosity are likely responsible for a significant fraction of bulk defects, and future work will aim to investigate the effects of resin distribution, degree of penetration, and surface topography on defect control phenomena and robustness.

Broadly, this work represents a step toward addressing a growing need for rapid, flexible, robust, and cost-effective high-performance composite manufacturing techniques. Rising demand for composite structures, limited availability of autoclaves, and the inherently unsuitable nature of autoclave processing in some scenarios (e.g. in-field repair, large structures) will continue to drive the need for such techniques. The approach presented here effectively transfers the robustness of autoclave cure into the material itself, and further development will accelerate the adoption of VBO prepregs as enabling technologies for numerous applications of composites while reducing barriers to entry.