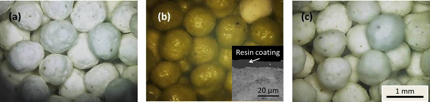

Light microscope images of (a) bare proppant pellets, (b) resin coated pellets (the inset shows a SEM micrograph of the resin coating layer), and (c) inhibitor infused pellets

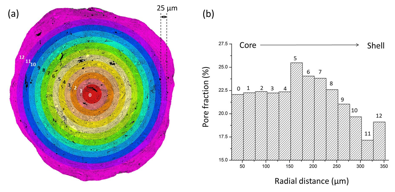

(a) Ring areas from which the pore fraction was calculated, (b) pore area fraction as a function of radial distance,

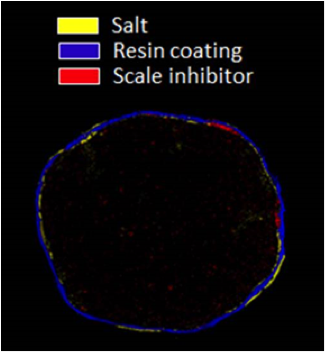

(c) EDS elemental mapping of a proppant cross section

Student Researcher:

Yuzheng Zhang

Summary:

The oil and natural gas stored in tight shale formation becomes available thanks to the breakthroughs in horizontal drilling and hydraulic fracturing (also known as fracking) techniques. Fracking is the use of fluid and material to create small fractures in a shale-rock formation in order to stimulate production rate from new or existing oil and natural gas wells. In fracking, a wellbore is first drilled vertically down for 5,000 to 10,000 feet, followed by horizontal drilling along the shale rock formation to maximize the contact area between the wellbore and the reservoir. A wire installed with explosive charges is then dropped in the well and set to fracture the wellbore casing and surrounding rocks. These cracks are further fractured open and extended by flushing down millions of gallons of high speed fracking liquid under an extremely high pressure of 6,000 to 10,000 psi. When the fracking pressure is reduced, proppants (propping agents) are needed to keep the fracture propped open. Many materials have been used for proppants including sand, glass beads, walnut hulls, and metal shot. Recent researches proposed the use of ceramics for light-weight proppants sintered from bauxite or kaolinite powders. Thanks to its porous structure, this low-density proppant requires less fracking liquid pressure to maintain proppant transport within the fracture and thus reduce the production cost. Unlike other porous low-density materials, the ceramic proppant is inherently strong to withstand high closure stress under well condition. Unlike silica sand, sintered ceramic proppant usually exhibits a spherical shape, creating more open space among proppant packs and thus increase conductivity of the well. In addition, the spherical shape helps to decrease the possibility of having stress concentration on sharp edges and therefore reduce the risk of being crushed into finer particles.

Another attractive feature of the ceramic proppant is that its porous structure can be infused with chemicals used for well treatment. Many chemicals are added to the fracking liquid to ensure fracking activity operates properly. The number of chemical additives used in a typical fracture treatment depends on the conditions of a specific well. A typical fracture treatment will use very low concentrations of between 3 to 12 additives including friction reducers, acids, surfactant, gelling agent, iron control corrosion inhibitor, scale inhibitor and biocide, etc. Each additive serves a specific engineering purpose. Conventionally, these chemical additives are squeezed into perforations or added to fracking liquid during fracking operation. As an alternate approach, these additives can be infused into the interconnected pores in the ceramic proppant which makes it a multi-functional propping agent in the well treatment. Infused ceramic proppants are capable of delivering additives throughout the entire production system in a more cost-efficient and long-lasting way. In addition, a resin coating can be applied not only to contain fines but also to control the chemical releasing rate. Understanding and controlling the elution rate of the infused chemical will be critical to defining the value of the product to market.

In this work, kaolinite based ceramic proppants infused with a phosphonate type scale inhibitor was systematically studied. Three infusion methods were investigated in terms of the infusion quality using energy dispersive X-ray spectroscopy (EDS). To evaluate the chemical elution rate, infused proppant pellets were “washed” by passing a certain volume of fracking liquid through the proppant pack. The amount of additives remained after the elution was semi-quantified using EDS elemental mapping.