Project Title:

Manufacturing of Complex Geometries Using Out-Of-Autoclave Prepregs

Researcher:

Yijia Ma

Summary:

Out-of-autoclave (OoA) prepreg processing has been developed as an effective alternative to autoclave cure, and can provide technical, economical and environmental benefits compared to conventional manufacturing. OoA processing can be used to produce flat laminates with autoclave-level microscrutcture and geometric quality without difficulty. However, the limited compaction pressure available during manufacturing and distinctive characteristics of VBO prepregs render the production of parts with complex geometries challenging.

The present study seeks to understand the effect of corner geometry on the consolidation phenomena of OoA prepregs and identify key parameters that affect the quality of contoured laminates, with the overall aim of developing aim of developing feasible reduction or elimation strategies.

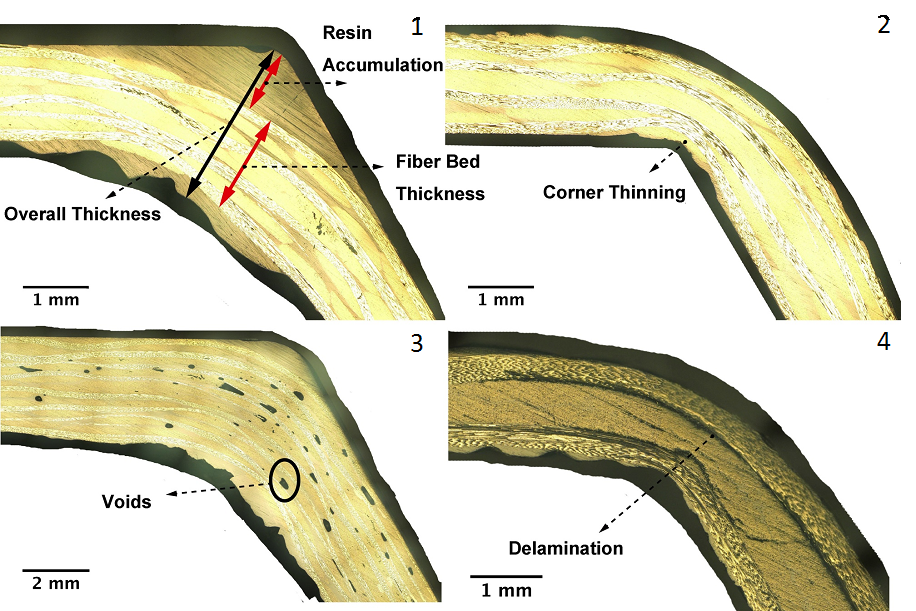

Composite optical micrographs of common defects ovserved in corner laminates manufactured using OoA prepreg: 1) Corner thickening, 2) Corner thinning, 3) Voids, 4) Delamination.