Out-of-autoclave/vacuum bag-only (OOA/VBO) prepregs initially feature dry areas that allow air evacuation at room temperature, and are infiltrated with surrounding resin during cure. These phenomena, and the part’s eventual performance, are highly dependent on the resin’s thermomechanical properties. These properties are generally controlled by ensuring the desired cure temperature is uniform within the part and by limiting the out-time, or time spent at room temperature. However, in industrial practice, for the large parts often found in OOA applications, both thermal and out-time control are challenging. Therefore, accurate, real-time, in-situ measurements of the resin’s state before and during cure are desirable.

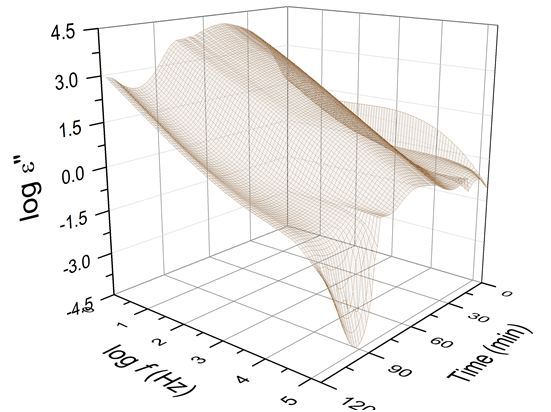

The present study investigates the use of a dielectric cure monitoring (DCM) system to track the out-time and determine the cure kinetics and viscosity evolution of an OOA/VBO prepreg based on Cytec’s Cycom 5320-1 out-of-autoclave prepreg resin. Prepreg resin samples exposed to different out-times are placed in an instrumented test cell, and dielectric properties such as the conductivity, permittivity and dielectric loss are obtained at room temperature. Then, these properties are tracked while the samples are cured under various cure cycles. The dielectric data set is then compared to resin cure kinetics and viscosity data obtained from neat resin by differential scanning calorimetry and parallel plate rheometry. This comparison identifies correlations between out-time, dielectric response and resin degree of cure, and between the evolution of dielectric properties, rate of cure, and viscosity change.