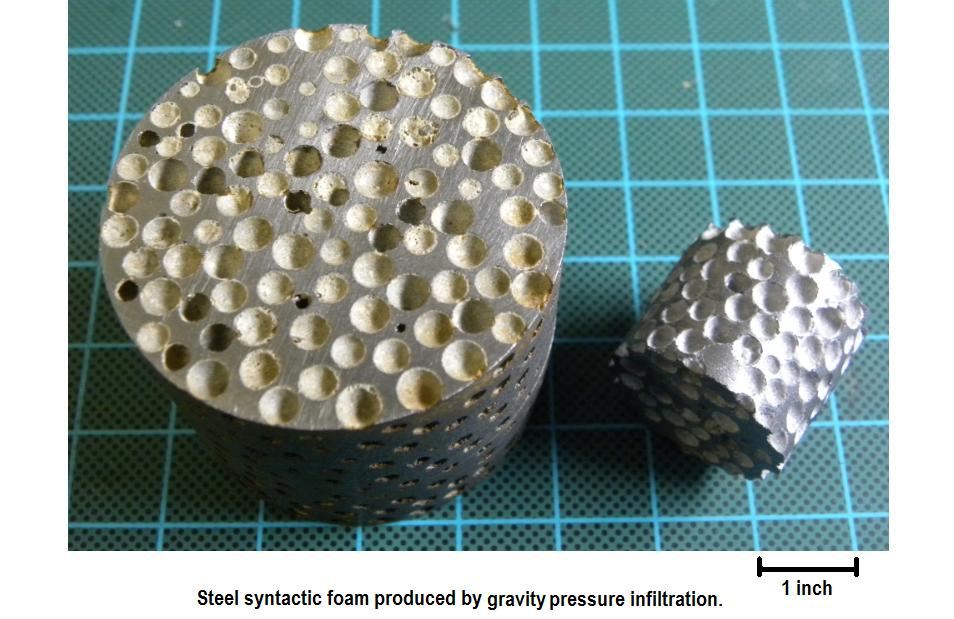

Steel syntactic foam offers potential advantages over aluminum foams and other metallic foams. The inherent strength of steel combined with the reduced density of foam presents an attractive material with greater strength and modulus than light alloy foams, greatly reduced density relative to solid steel, and efficient energy absorption. Metallic foams are produced at USC by liquid state processing, using two synthesis methods (mechanical pressure infiltration and gravity pressure infiltration) to consistently produce lab-scale foam samples with uniform distributions of microspheres and negligible unintended porosity.

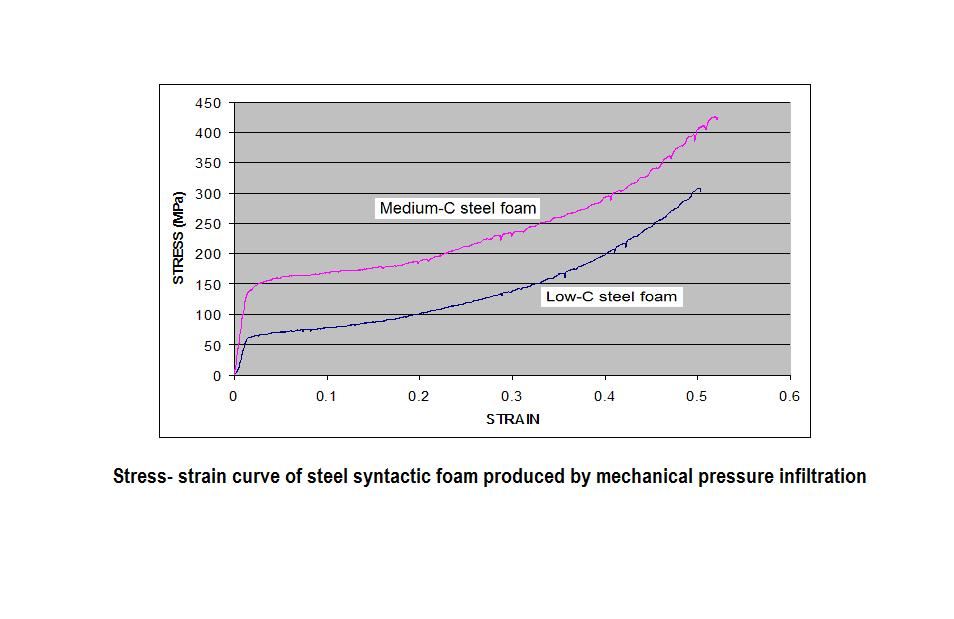

Production of steel syntactic foam is more challenging than aluminum foam, primarily because of the much higher melt temperatures required. The proposed methods of producing syntactic steel foam require only low-cost materials (low-carbon steel and alumina microspheres). Hollow alumina microspheres are used because of the inherent resistance to high temperatures (molten steel) and high strength. Syntactic foams with relative density of 0.54(microsphere diameter 1.27 mm) and 0.46 (microsphere diameter 4.45 mm) were achieved respectively. A fifty percent reduction in weight and an increase in impact energy absorption make syntactic steel foam an attractive candidate for armor applications in military vehicles and improved crashworthiness in civilian vehicles, competitive with conventional solid steel alloys. The basic mechanical properties of the steel syntactic foam are being studied under compression loading. Prospects and challenges for achieving higher energy absorption capacity using different steel matrices and modifying the microsphere volume fraction are being considered also.