Schematic of scarf patch demonstrating the need for through thickness air evacuation pathway during repair

Polished section micrograph of a repair patch demonstrating the quality of USC prepregs. Despite not including DVD and additional debulking steps, the parts made with USCpreg demonstrate minimal interior porosity.

Researcher – David Bender

Carbon fiber composites often sustain damage in service that requires structural repair. Restoring damaged structures is critical for longevity and in many cases safety. Parts are often replaced to ensure high quality yet complex structures or in-field conditions render this method impractical. Composite repairs are a challenging manufacturing problem because of the inherent challenges of performing repair, especially when performed in the field. Scarf repairs are the most common technique for repair due to the strength restoration. Current methods for in-field repair include wet layup and double vacuum debulking. These seek to address the challenges of prepreg storage and repair quality albeit not always successfully.

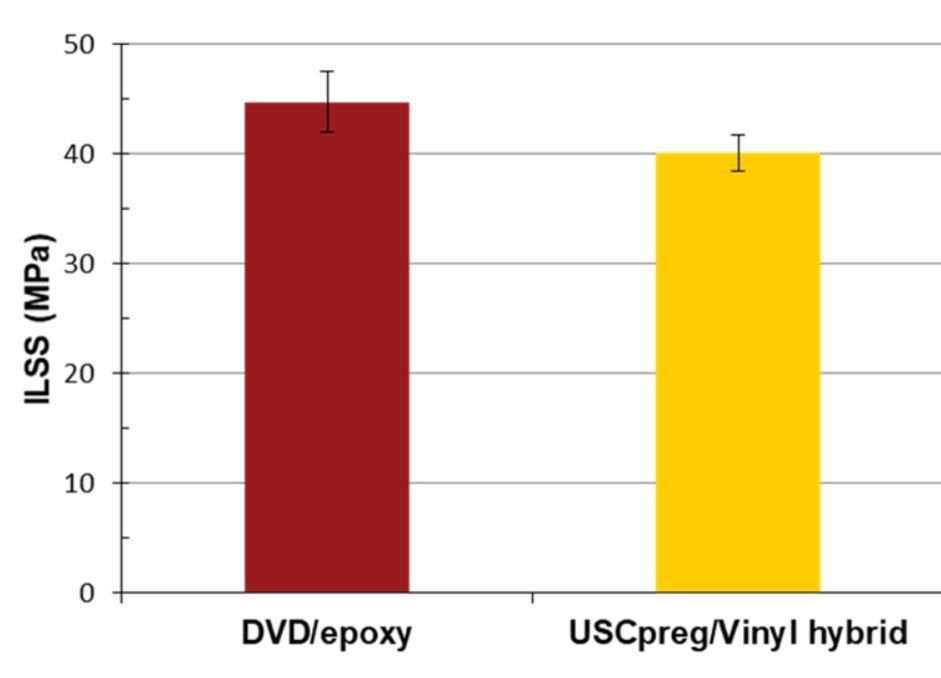

Here are USC we are seeking to address the issues of material storage and repair quality through the design of new prepregs employing novel resins and formats. We have developed prepregs capable of room temperature storage which don’t require double vacuum debulking to robustly manufacture parts with minimal porosity. A unique combination of USCpreg and vinyl hybrid resin has allowed for simplified, robust repairs. We are studying the effects of varying manufacturing conditions have on repair quality and strength.